“It’s probable Mount Polley will get a permit to open in the next couple of weeks.” – Bill Bennett, British Columbia Energy and Mines Minister, June 30, 2015

After the tailings dam breached at Mount Polley mine in British Columbia, Canada, last August and discharged contaminants into a Fraser River tributary, Alaska developers urged the public to avoid speculation on the cause and wait for a thorough investigation to be conducted. The Mount Polley breach would provide lessons for mining companies all over the world, Pebble Limited Partnership (PLP) CEO Tom Collier said.

Now that the mine is likely to reopen, what lessons have been learned?

At the time of the breach, some Alaskans expressed concern about the dam failure for a few reasons. Mount Polley is owned by Imperial Metals, the same company that recently opened the Red Chris copper mine upstream from the Stikine River, noted as one of the largest salmon habitats in Southeast Alaska’s Tongass National Forest. Additionally, the engineer of record for the failed tailings dam at Mount Polley is Knight Piesold, the same company PLP contracted to design the tailings facility at the proposed Pebble mine.

In January a team of mining engineering experts – acting as the Independent Expert Engineering Investigation and Review Panel – completed an inquiry into the cause of the Mount Polley breach. (The team was not charged with finding out who was responsible, only for how it happened). The panel determined that the Mount Polley tailings storage facility (TSF) failed due to an initial design flaw that did not take into account how some of the unconsolidated glacial materials would change over time as the load on the foundation increased.

In response to the report, PLP issued a statement that said, “PLP CEO Tom Collier has committed to submit the engineering design for the project’s tailings storage facility to an independent review prior to initiating permitting.”

Involving Independent Tailings Review Boards (ITRB) in the design, construction, operation and closure phases of a TSF is one of the recommendations by the Mount Polley review panel. The panel also detailed many other recommendations, including methods to reduce the risks of tailings dam failures for new mines.

The panel looked at TSF failure frequency rates and determined that, under typical conditions, an average of two TSFs with surface water would fail every 10 years in British Columbia. The authors recommend “filter-pressed, dry stacking” tailings for new mines to prevent such failures.

“Improving technology to ensure against failures requires eliminating water both on and in the tailings: water on the surface, and water contained in the interparticle voids. Only this can provide the kind of failsafe redundancy that prevents releases no matter what.” Report on Mount Polley Tailings Storage Facility Breach, p. 120.

Two Alaska mines – Greens Creek and Pogo – have been cited in academic and industry reports for their use of dry stacking. The filtered tailings method is still an uncommon approach, mainly because upfront and operational costs are higher than with conventional tailings management, which calls for water to cover the tailings materials “in perpetuity.”

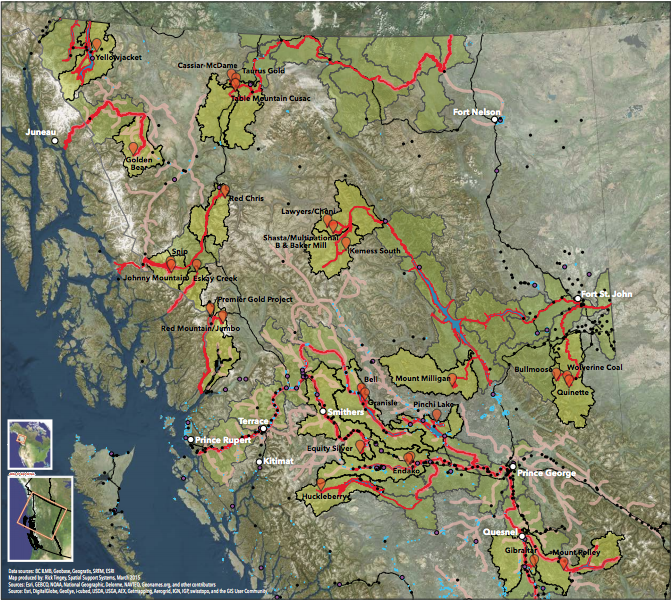

| “The full extent of contaminant flow paths in the event of future tailings pond facility failures within Northern British Columbia and Southeast Alaska.” – BC First Nations Energy and Mining Council report, June 2015

|

As evidenced by the Mount Polley breach, the direct and indirect cost of tailings dam failure is considerable. Imperial Metals is experiencing financial difficulties because of the shutdown, associated costs of cleanup, and lower-than-anticipated production at its new Red Chris mine. Major investor N. Murray Edwards recently loaned the company $25 million so it wouldn’t default on another loan it took out to fund cleanup efforts. Cleanup and recovery efforts are expected to continue through summer of 2016 and beyond. Water quality testing, internal investigations, public communications, and responding to government inquiries all require financial resources too.

The shut down has impacted the local economy, with more than 200 jobs lost and anxiety about whether the mine will reopen.

This spring Imperial Metals developed and submitted its application to reopen, which if approved by the government, would allow it to work at half capacity for six months.

Impacts to the fishery itself are still unknown, although researchers from the University of Northern British Columbia have identified waste materials present in the lake they say could affect the metal content of aquatic food webs and pose a potential hazard to the “growth, survival, and behavior of important fish species.”

Additional investigations are forthcoming from the Canadian government. Imperial Metals has launched its own internal investigation. Last month the BC First Nations Energy and Mining Council published a GIS-based analysis of northern British Columbia and Southeast Alaska to show areas that would be impacted by a failure in existing tailings facilities. It called for a high priority to be placed on protecting ecosystems from industrial activities, as well as ensuring that communities are protected by funding mechanisms against unintended impacts such as clean up and remediation.

Which of the lessons and recommendations from these findings will resonate with developers, regulators and the public in Alaska?

Read more:

Decision on Mt Polley mine re-opening “imminent”: B.C. mines minister

“Report on Mount Polley Tailings Storage Facility Breach”

Mount Polley Update Bulletin – April 2015

Filter-pressed, drystack tailings (Technomine article)